C Perkin products are designed and built to support the demands of the recyclable packaging and industrial core winding industries. The equipment benefits from many years of experience and expertise within the spirally wound tube making industry where an environmentally friendly and sustainable product is a primary focus.

Mako Range of Inline Flying Knife Units

Mako Multi 200 Inline Knife

The Mako Multi 200 Inline Knife benefits from 6 axis servo motion which brings quality, repeatability and accuracy to the inline cutting process. Automated tooling setup coupled with a knife location jig greatly reduce change over times whilst a fully configurable knife plunge force maximizes tooling and blade life.

Mako Mini Inline Knife

The Mako Mini benefits from 3 axis servo motion is designed to achieve high speed and accuracy for small diameter tube applications. Excellent visibility of the vertical inline knives provide a clear view of the process and aids fast setup.

Mako Midi Inline Knife

The Mako Midi inline knife 4 axis servo motion system delivers speed, accuracy and quality. The three point support system maintains tube stability whist the body pivot and side-lay functions allow perfect alignment to the upstream process. Automatic support and knife positioning greatly improves setup and changeover times.

Mako Maxi Inline Knife

The Mako Maxi benefits from all the functionality from the Mako Midi with an emphasis upon heavy duty industrial cores. Designed with robustness at it’s heart, the Mako Maxi delivers reliability and finesse at an industrial level.

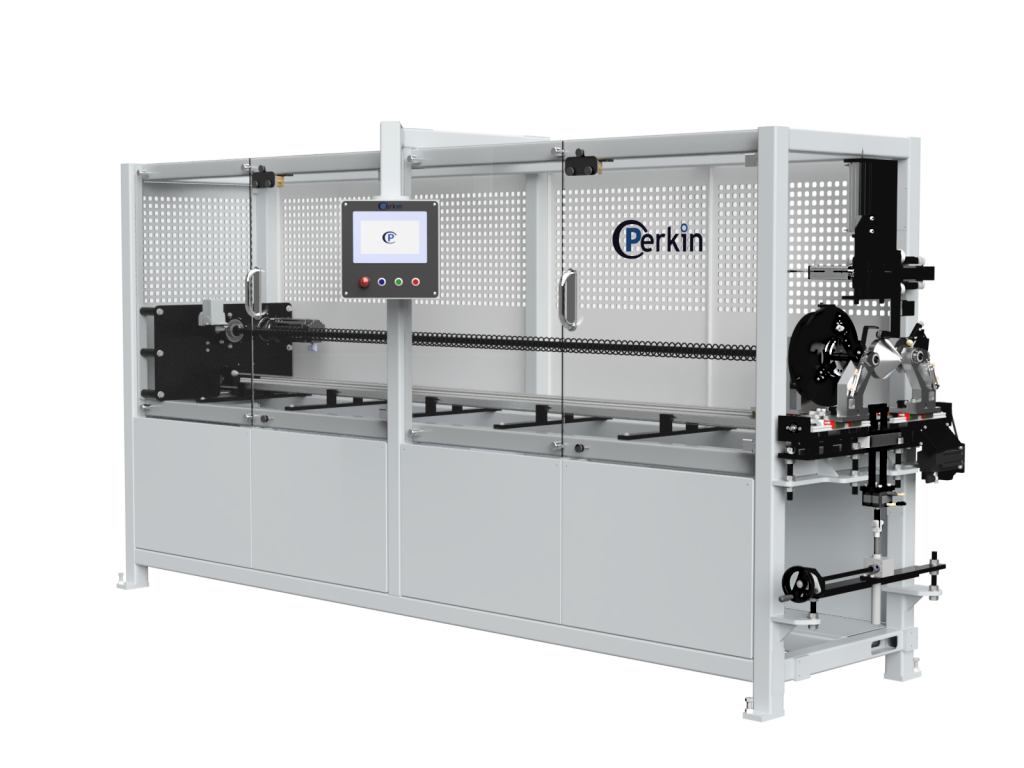

Manta Range of Spiral Winders

Manta Spiral Winders

The Manta spiral winder represents the driving force for any spirally wound tube application. The Manta range of spiral winder can be fully integrated into a production line or used as a stand-alone option to complement existing equipment. The Manta range uses class leading inverter technologies to increase reliability and efficiency of operation. This technology also provides a stable winding process which significantly increases the stability of down-stream equipment associated within the production line.

Glue Systems

Glue Systems

C Perkin have a wide range of gluing systems to suit different tube production applications and environments from simple cascades to advanced automatic dosing systems. Drawing from our vast experience our gluing products have been optimised to better suit a particular product requirement. All our systems are robust, reliable and efficient. Built to meet and better the required demand.

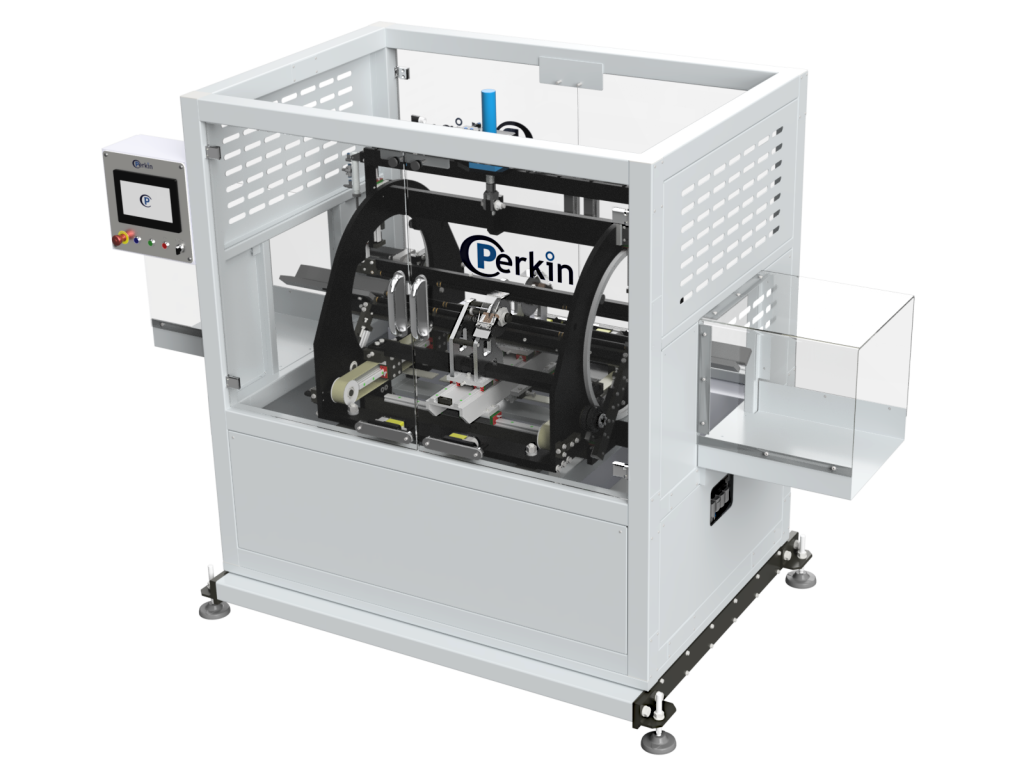

Falcon Core Re-cutter

Falcon Re-cutters

The Falcon range of core re-cutters offer industry leading speed, accuracy and quality of cut. The unit can be configured in conjunction with a semi-automatic core loading system to further increase to autonomy of the re-cutting process. The final product is handled using an outfeed conveyor system further reducing the need for secondary handling of the finished product.

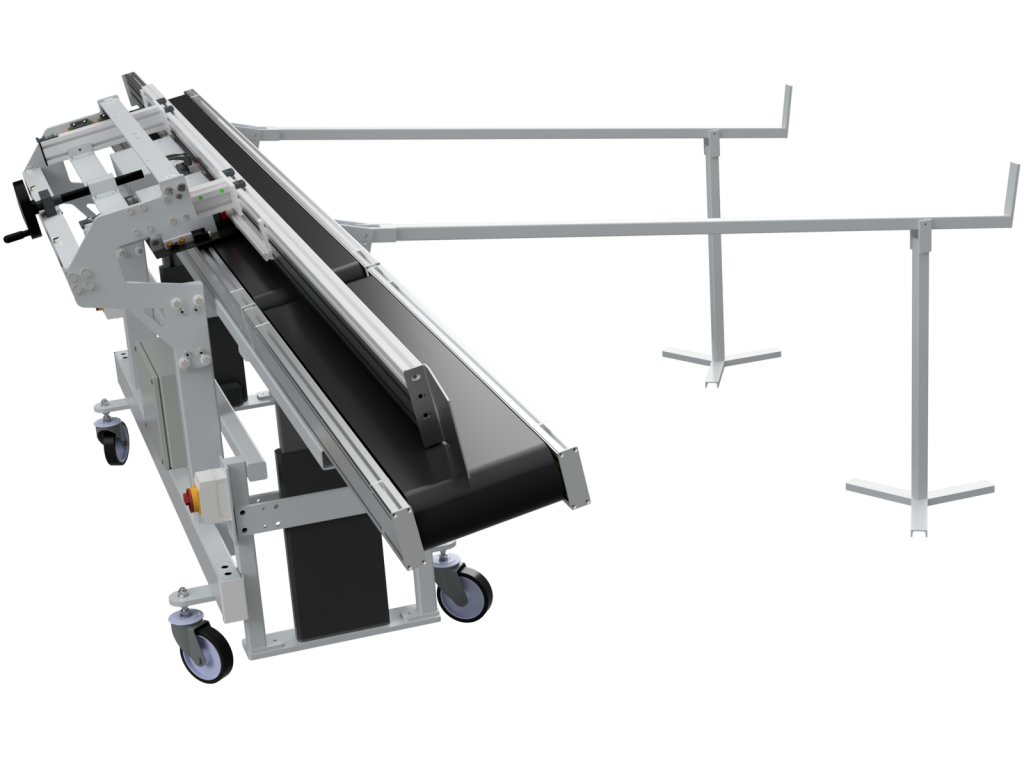

Ancillary Equipment

Ancillary Equipment

C Perkin offer ancillary equipment to fully support the requirements associated with the spirally wound tube packaging industry. This includes product conveying and handling systems, hermetic sealing units, paper edge tracking systems, automatic splicing units, paper accumulators, tube hoppers and collectors and many more…