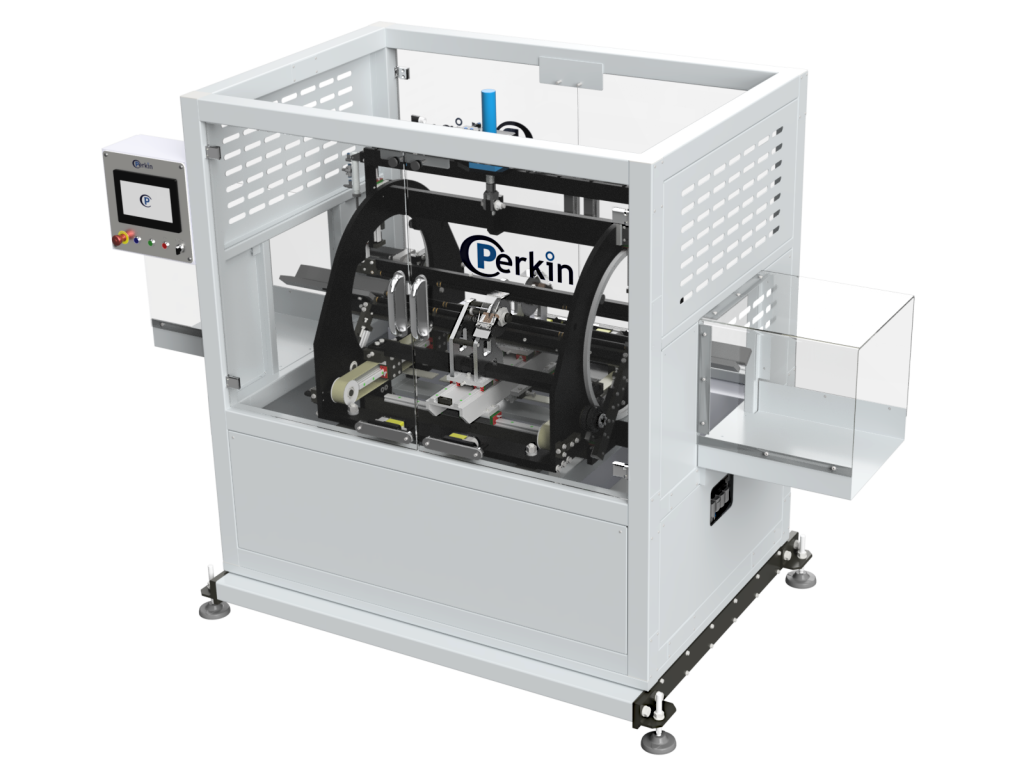

Mako Mini Inline Knife

The Mako Mini benefits from 3 axis servo motion is designed to achieve high speed and accuracy for small diameter tube applications. Excellent visibility of the vertical inline knives provide a clear view of the process and aids fast setup.

Mako Mini – Key Features

- Robust powder coated steel frame.

- 3 Axis servo control provides fully co-ordinated synchronous motion ensuring efficiency and reliability.

- Intuitive knife teaching optimises the cutting process profile to suit the product characteristic and hence, maximises uptime and reduces waste.

- Co-ordinated motion of knife carriage and internal cutting bullet is fully synchronized to the growing tube to deliver an accurate and repeatable product every time.

- Automatic incremental offset of the internal cutting bullet distributes the wear due to the knife impact and greatly extends tooling life.

- Vertical opposed knives which are optimized for smaller diameter cores deliver a synchronous and coordinated cut of exceptional accuracy and repeatability.

- Safety interlocked tempered glass access doors provide excellent visibility of the production process which enables the user to quickly identify and resolve setup issues.

- Fully compliant with current safety standards and issued with a declaration of conformity.

Mako Mini – Specification

| Minimum Tube Diameter | 8mm (ID) |

| Maximum Tube Diameter | 90mm (OD) |

| Maximum Tube Wall Diameter | 6mm |

| Minimum Cut Length | 80mm |

| Maximum Cut Length | Unlimited |

| Maximum Cut Cycles Per Minute | up to 120 |

| Repeat Length Accuracy | 1% (typical) |

| Maximum Rate of Inline Tube Growth | 60m/minute |

Mako Midi Inline Knife

The Mako Midi inline knife 4 axis servo motion system delivers speed, accuracy and quality. The three point support system maintains tube stability whist the body pivot and side-lay functions allow perfect alignment to the upstream process. Automatic support and knife positioning greatly improves setup and changeover times.

Mako Midi – Key Features

- Robust powder coated steel frame.

- 4 Axis servo control provides fully co-ordinated synchronous motion ensuring efficiency and reliability.

- Intuitive knife teaching optimises the cutting process profile to suit the product characteristic and hence, maximises uptime and reduces waste.

- Co-ordinated motion of knife carriage and internal cutting bullet is fully synchronized to the growing tube to deliver an accurate and repeatable product every time.

- Automatic incremental offset of the internal cutting bullet distributes the wear due to the knife impact and greatly extends tooling life.

- Horizontal opposed knives which are optimized for small to medium diameter cores deliver a synchronous and coordinated cut of exceptional accuracy and repeatability.

- Safety interlocked tempered glass access doors provide excellent visibility of the production process which enables the user to quickly identify and resolve setup issues.

- Fully compliant with current safety standards and issued with a declaration of conformity.

- A robust automated tube support system ensures quick size change overs.

- Motorised Body Adjustment. With the touch of a button the machine can easily be adjusted for both angle and lateral position. This feature ensures the machine can effortlessly be aligned to the tube, which greatly improves the cut quality.

Mako Midi – Specification

| Minimum Tube Diameter | 25mm (ID) |

| Maximum Tube Diameter | 320mm (OD) |

| Maximum Tube Wall Diameter | 20mm |

| Minimum Cut Length | 80mm |

| Maximum Cut Length | Unlimited |

| Maximum Cut Cycles Per Minute | up to 120 |

| Repeat Length Accuracy | 1% (typical) |

| Maximum Rate of Inline Tube Growth | 60m/minute |

Mako Maxi Inline Knife

The Mako Maxi benefits from all the functionality from the Mako Midi with an emphasis upon heavy duty industrial cores. Designed with robustness at it’s heart, the Mako Maxi delivers reliability and finesse at an industrial level.

Mako Maxi – Key Features

- Robust powder coated steel frame.

- 4 Axis servo control provides fully co-ordinated synchronous motion ensuring efficiency and reliability.

- Intuitive knife teaching optimises the cutting process profile to suit the product characteristic and hence, maximises uptime and reduces waste.

- Co-ordinated motion of knife carriage and internal cutting bullet is fully synchronized to the growing tube to deliver an accurate and repeatable product every time.

- Automatic incremental offset of the internal cutting bullet distributes the wear due to the knife impact and greatly extends tooling life.

- Horizontal opposed knives which are optimized for small to medium diameter cores deliver a synchronous and coordinated cut of exceptional accuracy and repeatability.

- Safety interlocked tempered glass access doors provide excellent visibility of the production process which enables the user to quickly identify and resolve setup issues.

- Fully compliant with current safety standards and issued with a declaration of conformity.

- A robust automated tube support system ensures quick size change overs.

- Motorised Body Adjustment. With the touch of a button the machine can easily be adjusted for both angle and lateral position. This feature ensures the machine can effortlessly be aligned to the tube, which greatly improves the cut quality.

Mako Maxi – Specification

| Minimum Tube Diameter | 50.8mm (ID) |

| Maximum Tube Diameter | 650mm (OD) |

| Maximum Tube Wall Diameter | 20mm |

| Minimum Cut Length | 70mm |

| Maximum Cut Length | Unlimited |

| Maximum Cut Cycles Per Minute | up to 120 |

| Repeat Length Accuracy | 1% (typical) |

| Maximum Rate of Inline Tube Growth | 60m/minute |

* Note: The maximum products per minute is based upon using six knives and five useable products per cycle.